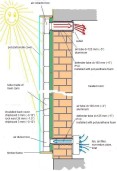

Solar heater made of beer-cans

Dear Reader,

First of all look at this site, please:

I was inspired by these things which have been found here by

me to build a similar one tentatively. It's a solar collector system

for heating supplement which warms air. It has a quaint feature: it's

built with empty aluminium beer-cans thus while we haven't found a

better name I will mention it as a "beer-collector".

You can read a detailed summary about this theme and steps of

the making on this Hungarian forum:

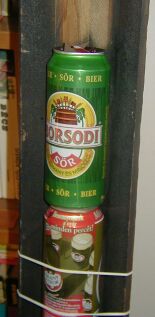

First of all I collected empty beer cans. You need to clean

boxes immediately, because those are very fetid. Attention! Beer-cans

are made of aluminum generally, but there are some cans made of iron.

You can test these cans by a small magnet.

When I collected enough cans I drilled each cans below and

above. I used a similar tool which has shown on Picture 1 and 2. Its

diameter is 44 mm, 1.75 inches. Set 45-60 revs per minute. This tool

has an ingredient for the centralization but unnecessary to use that in

this occasion.

|

|

|

|

Picture 1 |

Picture 2 |

Picture 3 |

WARNING! This operation is very

dangerous because walls of the cans are very thin.

Those pieces can provoke any hand injury.

Use a hard plastic ring for own hand protection shown on

Picture 3. This ring has been made by a turner. The ring fits up and

down on the cans. When the drilling was finished the metal sometimes

did not break off. You can use any pliers to take out the fallen

scraps. .

Don't take out the scraps by hand!

Remove the grease from the cans' surface. Any synthetic

stain-remover is suitable for this. Execute this operation outside or

in a well ventilated room.

WARNING! This operation is flammable

and potentially explosive!

The usage of an opened flame and

smoking to be neglected!!

Glue the cans by any heat-resistant adhesive. The adhesive

must be heat resistant at least up to 200 °C. There are

heat-resisting adhesives up to 280 °C or 300 °C too. The roof of

the beer cans and they bottom adjust to each other. If you prepare a

bore with 44 mm diameter, so a little edge stays on the roof. Put some

adhesive onto this part round, and press the bottom of the other box

into it. In this manner the adhesive don't escape from the edge. After

drying the glue will be adequate elastic and stuffed. A detail of the

glued cans is visible on Picture 4.

|

|

|

Picture 4 |

Picture 5 |

Prepare the trough which has been shown on Picture 8. Make it

from nailed planed timber and the pipes will be straight by this. The

pipes keep in this trough when the adhesive dries. Fasten the cans to

the trough with large fruit rubbers. Hang the rubbers onto the tiny

nails knocked in the rear side of the timber.

The small fins are made of the wispy disk gained from the side of the boxes. Their task to make a turbulent flow in the pipe, so the streaming air cuts more heat from the warmed box wall. Draw it with an alcoholic felt-tip pen, cut it out with a scissors, and then bend it with the help of pliers (Picture 5 and 7). Before gluing it is necessary to make the fins.

The Picture 6 and 10 show the gluing process. The cans glued

together form a pipe. The Picture 11 introduces a pipe, which stays in

the trough, during the drying of adhesive..

Picture 6 |

Picture 7 |

Picture 8 |

|

Picture 9 |

Picture 10 |

The divisor/collector boxes have built with 1mm aluminum

sheets (Picture 12); the gaps at the edges have been caulked with heat

resistant adhesive. The lids of boxes have cutting with a diameter of

55 mm tool on a stand drill. The pierced roofs are visible on Picture

13. The first row of cans has been glued into the lid of the divisor.

(Picture 14 and 15). The next picture shows the divisor,

collector and the absorber which have been put together before

painting.

The adhesive's drying is very slow. It is necessary to let it dry during at least 24 hours.

Picture 14 |

Picture 16 |

|

Picture 12 |

||

|

|

||

The absorber gets into a box which was made of timber (Picture 17). The reverse side of the box was made of chipboard, for stiffening I developed planks into cassettes. The rock-wool got into these cassettes. These all are covered by thinner chipboard. The installed insulator is visible on Picture 18. Already it has been covered on the opposite part. It is necessary to surround the holes with planks at the inlet and outlet, to fixing the insulation.

|

|

|

Picture 17 |

Picture 18 |

The box got preparatory timber protection, and then I painted

it. I applied four ears onto his four corners to install it to the wall

(Picture 19). I placed the empty frame box to designated place of the

brick-wall. I used 10 mm stem screws for this operation. Finally I

chiselled the brick-wall at the nominated place (Picture 20).

|

|

|

Picture 19 |

Picture 20 |

After that the black-painted absorber has got into the frame. The frame got a cover which has been made of polycarbonate sheet. It has been clamped with an aluminum-profile by me.

The polycarbonate sheet is slightly convex, that let him be

more rigid a bit. The installed absorber is visible without cover on

Picture 21. The complete solar heater on the floor is visible on

Picture 22, and the eventually installed heater is visible on the

Picture 23 and 24.

Picture 23 |

Picture 21 |

Picture 24 |

Picture 22 |

Data:

|

width: |

1238 |

mm |

|

height: |

2966 |

mm |

|

most thickness: |

180 |

mm |

|

full surface: |

3,67 |

m2 |

|

useful surface: |

3,5 |

m2 |

|

weight: |

76 |

kg |

|

inlet diameter: |

100 |

mm |

|

outlet diameter: |

125 |

mm |

|

used cans: |

270 |

pieces |

|

installed fins: |

252 |

pieces |

|

position: |

vertical |

|

This system has a mistake: it isn't capable to store the

produced heat. When the Sun is shining it warms but it is necessary to

utilize the produced heat immediately. If the sun does not shine

inhibit an air flow in him, because it cools the room otherwise. It is

possible to solve it by a non-return valve with minimal heat loss.

A temperature difference switch controls the fan. It is

possible to buy it in electronic shops. It has two sensors. One of

these is installed into the upper effluent tube, the other one is

installed into the lower inlet.

If you set temperatures correctly it will produce about 1-2 kW

of heat energy. It is related to power of the sun.

The collector's dress rehearsal was in the garden before I was

installing him onto his definitive place, on 26 January 2006. It was on

a cloudless winter day, and the sun was radiating strongly. The air was

blown by a little fan, and I measured temperatures with thermometer. A

little anemometer measured the velocity of the air. I defined the mass

flow in the knowledge of the cross-section and I defined the

temperature's difference and then I calculated the power of the heater.

The outside temperature was -3 °C and more than half m3/min of

warmed air was streaming out from the heater. Its temperature was +62

°C. I was calculating from the measured data around 700 watts. If I put

the +/- 5% of tolerance into the rounding error of the displays, even

the 736 W result could have been calculated.

This is precisely 1 horsepower!!!

I wrote about this in the forum, namely in this manner: "...

the beer collector brought a horse from the Sun! It may be it was a

beer-horse! "

The experienced results are promising, the solar heater is suitable for

a heating supplement in sunny time.

(A little explanation to the understanding: The beer-collector

is a

pun, and the beer-horse is a pun too.

The "beer-horse" expression originates from the past when beer was

delivered into the pubs in Europe by carriages towed by horses. These

horses were burly animals, and they have been given a name as

beer-horses by the people.)

|

Implementation, photos 02, March 2006.

|

|